Case study

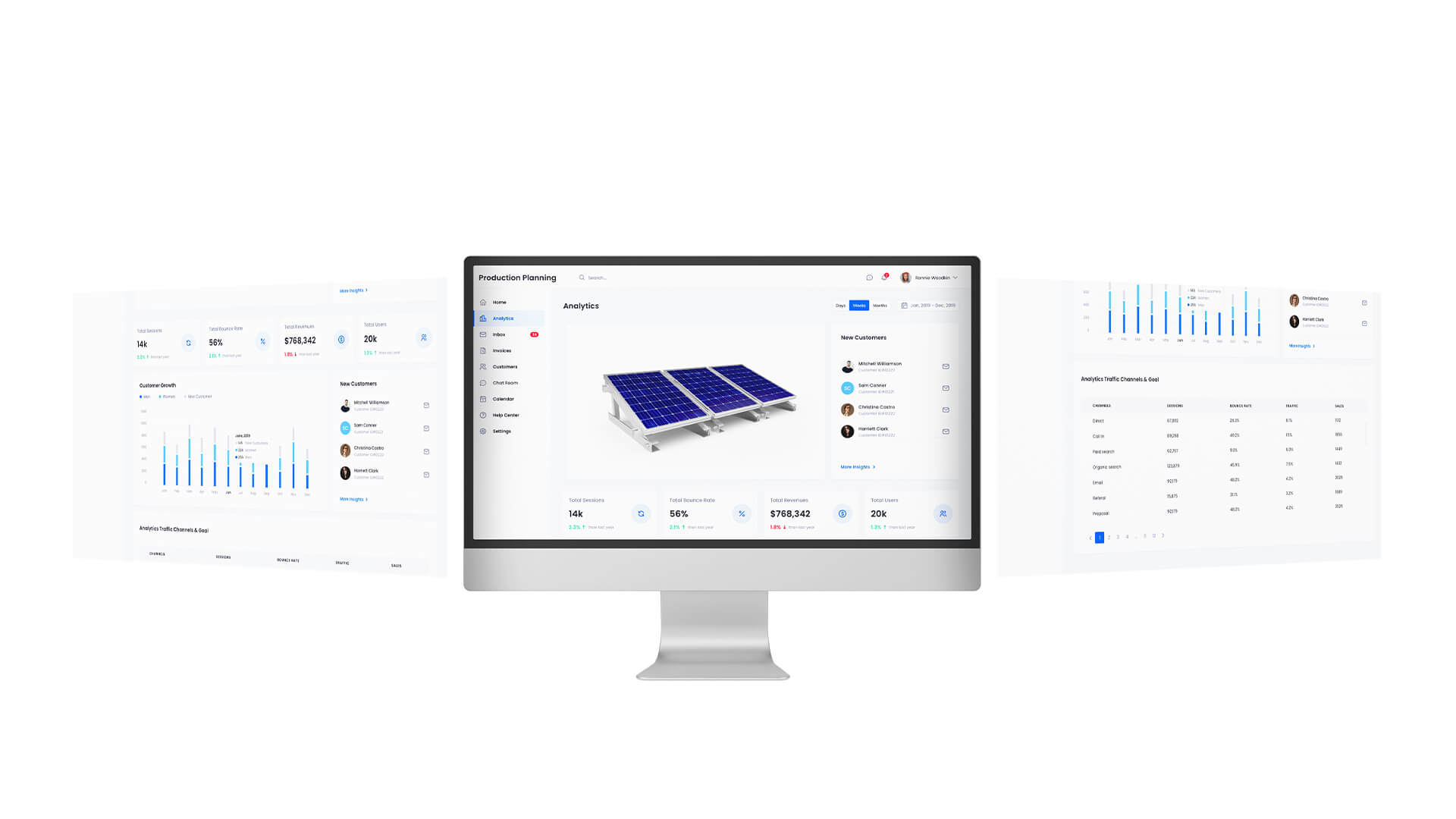

Monitoring Platform for Large-Scale Solar Plants

Highlights

- The charts, periodical reports and error notifications allow users to remotely monitor solar plants that rely on PV inverters.

- Reducing operational and maintenance costs by offering a self-diagnosis functionality for the solar inverters.

- The software analyses the performance of every connected inverter, and factoring in the performance of other, close-by devices can make the difference between false alarms and actual errors.

- The platform allows the users to remote control the solar inverters.

Technologies:

ASP.Net, Bootstrap, Typescript, .NET, MS SQL Server

Services:Software Development, Software Architecture, Manual Testing, Automatic Testing, Maintenance, Deployment

5

Team Size14+ Years

DurationManufacturing

Industry

Client Benefits

Intuitive UI

Intuitive user interface design for web and mobile apps that simplifies maintenance and error analysis.

Technical Know-How

Accrescent admin interface that allows the staff to execute administrative tasks directly from the user interface.

Partnership

Long-term collaboration with a constant self-sustainable core team that ensures the continuity of the project.