Scaling the Industrial Manufacturing Processes Through Production Planning Software

23 January 202429 November 2022 |

Production planning software has taken an increase in demand since the global pandemic took the industry by storm and left numerous plants without their workforce. Digitizing processes, products, and services through automation is part of the digital transformation roadmap for the manufacturing industry.

Table of Contents

- Production Planning Enables Smart Manufacturing

- The Benefits Enhanced by Production Planning Software Make the Digitization Of the Manufacturing Industry Tangible

- Conclusion

- simulating the end-to-end impact of business and market changes;

- optimizing store layouts by responding to shifting customer preferences;

- creating a true omnichannel experience that provides for seamless pause-and-resume customer journeys across channels through improved data tracking;

- enhancing next-best product recommendations with in-store data, such as browsing patterns and inventory levels.

- Planning quality: the APS system’s scheduling technique should include production characteristics as well as scheduling constraints in order to generate an accountable production and operations schedule for shop floor execution.

- Practical applications: It is preferable to integrate the APS with ERP and MES (Manufacturing Execution System) systems for the user to quickly generate production and operations schedules and respond to market demand changes.

- System expansion: the APS system model should be easily adjustable to the factory when it has newly released products, machines, or processes.

- With the UiPath solution, we help monitor SAP log transactions, monitor and classify support tickets, calculate available budget, assign billing invoices according to descriptions entered in a .csv file.

- With the Power Automate solution, we have created an application where employees can register their ideas of what processes would benefit from being automatic.

Production planning software for the manufacturing industry, along with production reporting software, plays an important role in the development of industry 4.0. It is the right support system to ensure that raw materials, workforce, and other necessary items are ready to create finished products within their scheduled time frame.

Production planning systems allow plant managers and business owners to focus on the production and delivery of goods and services rather than how to track production, make production forecasts, and schedule production resources. Real-time master planning, for example, can improve production scheduling, inventory management, and product quality, allowing for leaner production processes that work faster and with less waste.

“In 2020, the global advanced planning and scheduling (APS) software market was valued at 1.49 billion U.S. dollars and is projected to reach 2.94 billion U.S. dollars by 2028. APS software generates optimal production schedules and reduces overall downtime and errors, which helps manufacturers in the efficient allocation of raw materials and optimization of production capacities through organizing sales, purchase, production, and transportation activities. The software solutions help them plan and schedule production on the basis of material and labor availability, and current plant capacity.”

Source: Advanced planning and scheduling (APS) software market revenue worldwide from 2017 to 2028

Manufacturing reporting software works simultaneously within the APS (Advanced Planning and Scheduling) system, and it is essential due to its capacity to gather analytics about these operations and see how the manufacturing business is running day by day. To make more accurate decisions and respond faster, production reporting software can become an essential component in manufacturing operations because its sensor-enhanced capabilities can deliver full visibility of all physical and digital elements, allowing for enterprise-wide and customer-supply-chain interdependence.

Moreover, organizations can identify areas for action, simulate scenarios, and meet their sustainability goals with an accurate and transparent production reporting system that helps them minimize waste, reduce carbon emissions, and improve sustainable supply chain performance.

Setting a production reporting system within an advanced planning and scheduling system can bring benefits related to productivity and cost-effectiveness because of the decisions taken based on the insights released.

The planning stage develops the production strategy for labor, equipment, work centers, and material requirements. After the plan is created, routing determines the path raw materials take within the production plant before moving on to scheduling, which emphasizes “when” the operation will be completed.

Production Planning Enables Smart Manufacturing

As a manufacturer, the revolution of industry 4.0 is becoming hard to ignore and harder to implement. The reason behind it is built on the complexity and cost intensity of the transformation process, as well as data protection concerns and the changed requirements profile for the workforce. Because of this, only 5% of manufacturers have at least one plant at full smart status, but even so, 83% believe that smart manufacturing initiatives will transform how products are made.

Smart manufacturing is the funnel that powers the industry to automate for greater efficiency, enhance information flow and reduce operational costs. To achieve these results, manufacturers should take into consideration crucial elements like production planning software, industrial IoT, and cost management software.

Production planning software is one of the most efficient ways to add value to the supply chain and increase the plant operating systems. Overcoming the spreadsheet era by enabling digital lean within the manufacturing industry can offer access to an improved OEE while introducing technological developments such as digital twins.

Spreadsheets are useful tools for organizing data and conducting simple calculations, but they do not communicate or coordinate across the different elements of the business that must collaborate to carry out the manufacturing operations. Therefore, businesses should provide a new level of visibility in the plant, new software including advanced planning and reporting, and more comprehensive and capable “smart” systems that use simulation, such as digital twin, and optimization to develop and monitor realistic plans that boost productivity and help get the most out of all available resources.

Normalizing the digitization of operations is a must within the industry and it can be achieved only through smart manufacturing because it is the main component for responding to advanced customer demand, global competition, and the continuous need to increase speed and reduce cost.

Industry 4.0 can be achieved only through the intelligent interconnection of machines and processes with the support of information and communication technology which can be enhanced by the right mix of manufacturing software development services.

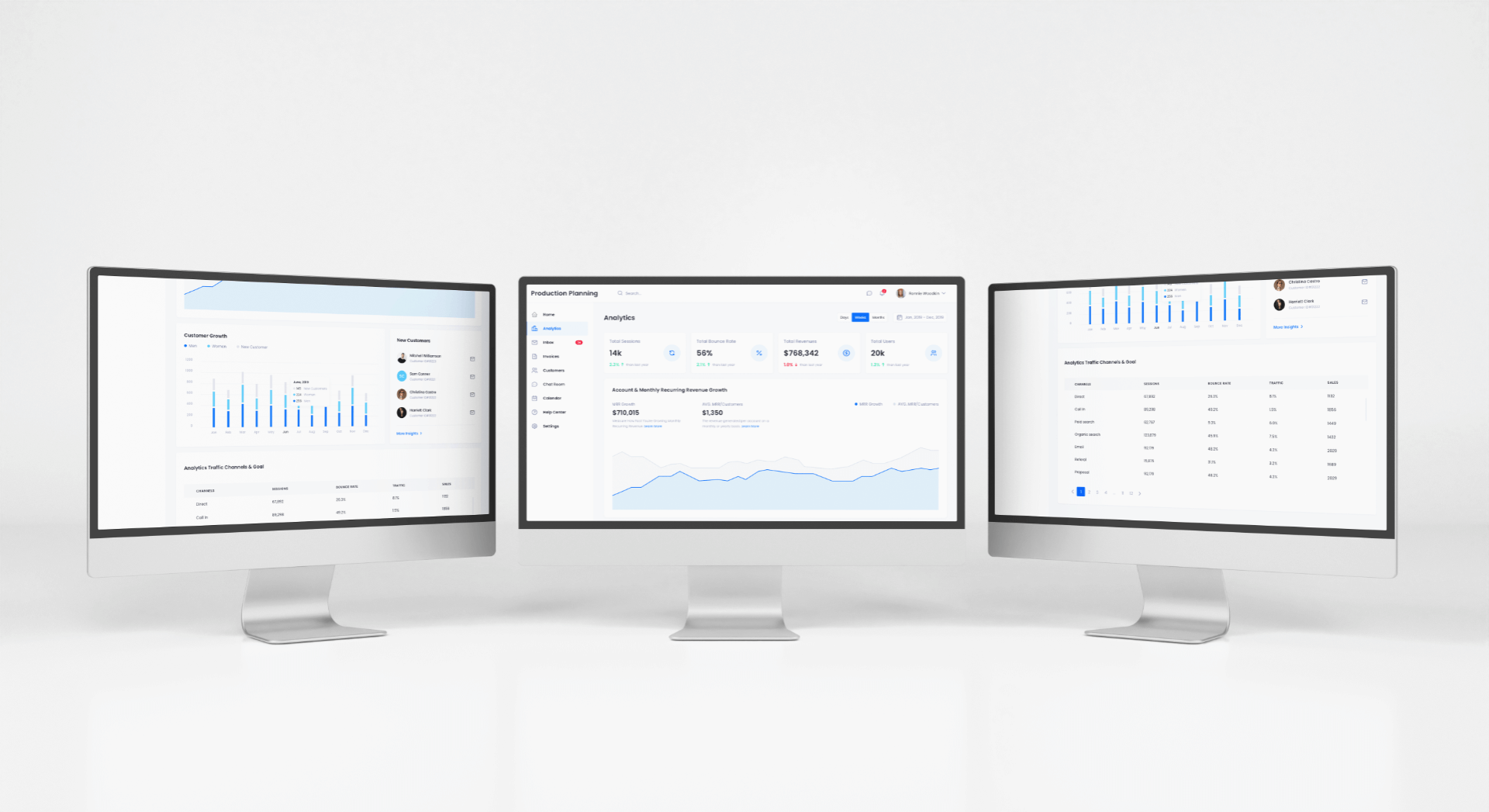

For example, Fortech focused its efforts on helping to develop a production planning software solution that provides factories with an overview of their material flow. The collaboration started from our client’s need to build their custom intralogistics and production planning.

The team worked on the project from architecture to implementation and the focus was directed on the material flow planning component. To begin with, our team created an ACAD plugin that allows the existing application to communicate with AutoCAD. The plugin allows the software to import physical factory plans created in AutoCAD, after which the user makes the necessary adjustments, and the data is exported back into AutoCAD.

By creating a digital twin of the facility, the software assists manufacturers with all phases of factory planning and optimization. Fortech’s manufacturing software team participated in the development of the application that facilitates processes ranging from logistical planning to material flow planning and can even reduce possible issues in assembly lines. With the push of a button, all of these can be efficiently designed, visualized, and simulated. This includes planning that originated from the initial greenfield concept and progressed to the actual factory building prior to the SOP (Standard Operating Procedure).

Our manufacturing software development team focuses on the solution that provides factories with an overview of their material flow. Depending on the industry and goods being produced, the material flow is optimized in terms of processes and resources. The application performs an initial analysis considering data such as resources, production capacity, necessary parts, workforce, shift allocation, etc., and then it starts mapping the layout.

The application allows the import of factory layouts created in AutoCAD. Users can build on the imported plans and export and reuse them in AutoCAD.

Nowadays, manufacturers must be highly attentive to trends and demand and be able to respond to those changes quickly and effectively. And, because manufacturing is now spread across the globe, very few things are produced in a single area, which means that the entire supply chain must be responsive and well-coordinated. With cost reduction in mind, more and more manufacturers are opting for OEM products because they can build systems at reliable quality, competitive pricing, faster production and a better return on investment. In the long run, businesses working with an OEM can expect to save money and reduce downtime.

“The automotive original equipment manufacturer (OEMs) market size is valued at USD 39,503.36 million by 2028 and is expected to grow at a compound annual growth rate of 3.4% over the forecast period of 2021 to 2028.”

Source: Global Automotive Original Equipment Manufacturer (OEMS) Market – Industry Trends and Forecast to 2030 Report

The Benefits Enhanced by Production Planning Software Make the Digitization Of the Manufacturing Industry Tangible

The most significant advantages of production planning software come from the coordination of operations in pursuit of a common goal: providing excellent customer service at the lowest possible cost and making the best use of available resources. That’s tremendously tough to achieve if the “plan” is on a spreadsheet, and a spreadsheet isn’t truly a plan at all because it’s impossible to convey across the business and supply chain and isn’t dynamically linked to ongoing activities.

Digital twin: Digital twin was born based on basic CAD documentation. With IoT support and the growth of BIM working processes, the concept of the digital twin has become a representation much closer to reality. Through digital twin, the CAD object that is portrayed in 2D or 3D demonstrates not only the form of the physical object but its behavior as well. For example, the AutoCAD plan facilitates the construction of a digital factory, but only through digital twins will the elements be able to interact between them and simulate the completion of plant processes.

A greater value is achieved if two or more digital twins are interconnected because they can generate richer behavioral insights. For example, an organization may connect its employee twin with digital twins of its customers, stores, inventory, sales, and customer process flow and gain benefits such as:

Another benefit of implementing digital twins is related to the interconnectivity of digital twin factories. This means planners can conduct a virtual walk-through factory plant at any time, from anywhere. They can develop production systems together in the simulated world, compare best practices and share information quickly and easily within the network.

The digital twin is benefit-oriented toward large-scale simulations for industrial applications as well. For example, digital twins are helping enterprises reimagine warehouse logistics from end to end and capture significant operational efficiencies which enable them to deliver more value to their customers. The key to these results is the ability to simulate these buildings and understand their performance before building them. A full-scale digital twin of the warehouse has been created, which helps the enterprise optimize the warehouse design, train more intelligent robot assistants, and gain operational efficiencies. Aggregating data sets from many different CAD applications, organizations can visualize these massive models in full fidelity realism.

“70% of C-suite technology executives at large enterprises are exploring and investing in digital twins. By 2025, the manufacturing industry is forecast to reach a market size worth over six billion U.S. dollars.”

Source: Digital twins: From one twin to the enterprise metaverse

Time saver: Traditional production scheduling methods, such as manually arranging each work on a spreadsheet, are exceedingly time-consuming and error-prone, but a customized RPA could be a real-timesaver for any manufacturer. The advantages of robotic process automation (RPA) enable organizations to automate repetitive tasks such as compliance reports, data entry, or automation of raw material orders, leading to increased OEE and allowing staff to focus on more essential responsibilities.

Reduce waste of resources and production costs by maximizing the OEE: A production scheduling software enables production costs by increasing efficiency. Production scheduling software facilitates planning weeks or even months ahead of consumer demand and it will guarantee improved availability, performance, and quality getting the most of all resources.

Costs for materials and components from various suppliers may be tracked in production planning software through a bill of material (BOM), enabling organizations to make the optimal purchasing choice based on price variations. A BOM assists organizations in planning material purchases, estimating costs, planning for and controlling inventory, and minimizing production delays and waste. An accurate, complete BOM aids in determining the root cause of a product failure and facilitates the replacement of faulty parts, materials, and components.

Maximizing OEE is also able through automated guided vehicles (AGV). AVG are material handling systems that travel autonomously throughout a warehouse, distribution center, or manufacturing facility, without an onboard operator or driver. With even better efficiency, factories can opt for AMR that navigates via maps that its software constructs on-site or via pre-loaded facility drawings. The AMR uses data from cameras and built-in sensors and laser scanners as well as software that enables it to detect its surroundings and choose the most efficient route to the target. It works completely autonomously, and it optimizes productivity by ensuring that material flow stays on schedule.

Allocate the exact number of employees: Having production planning software in place gives the organizations the opportunity to allocate an exact number of employees for the processes that need to be operated. This is possible because the planning software focuses on the solution that provides factories with an overview of their material flow. Material flow is optimized in terms of processes and resources based on the industry and items produced. Everything is done to guarantee an effective supply and layout. Having the exact number of employees allocated also helps with cost-effectiveness since the businesses don’t need to invest in more workforce than they actually need.

Transparency of data: Manufacturing reporting software systems enable various departments throughout a company to access and display the same consistent and accurate data in real-time. As a result, everyone from the engineering teams to the factory plant to the buying and finance departments has total insight into designs and plans, production status, quality control, inventory, cost of goods sold, and other information. This allows for more efficient coordination and execution of all relevant processes and operations. The results enabled by the manufacturing reporting systems are built on IoT. The latter facilitates transparency of data by employing a network of sensors to collect critical production data that is being converted into effective decision-making about manufacturing processes. For example, machine downtimes and damages can be critical to manufacturing companies, but IoT devices have various sensors that can monitor the temperature, vibration, voltage, currents, and more and can help with early warning signs of any predicted malfunctions, creating a safer workplace.

Improved collaboration between departments: Customized manufacturing planning software allows organizations to exchange critical production-related data with external stakeholders such as vendors, suppliers, and distributors in addition to internal personnel. This enhances communication and allows for greater activity coordination across these key business partners, offering visibility within the entire production ecosystem, starting from the entry of the raw materials in the factory, to the delivery of the finished product to the end customer.

In terms of practicability, an effective APS must fulfill the following aspects to run smoothly and provide all the benefits mentioned:

“A recent study by Oracle revealed that large financial institutions could lose up to $1.5 billion in revenue if they do not leverage new technologies fast enough. By contrast, those with advanced, cutting-edge solutions reported revenue growth of more than 8%.”

Source: Legacy Systems: A less disruptive digital transformation

A well-developed production planning software that is enhancing all these benefits should have included the SAP ERP technology to increase effectiveness on all levels, including cost management. Through SAP ERP production needs could be managed such as bills of materials (BOM), routing, materials requirement planning, and production orders. Also, customer demand can be addressed, and a sales forecast can be created. The production module, which is tailored to the needs of manufacturers, comprises core capabilities that help with everything from overall production planning to product delivery to customers.

For a recent project, for a multinational client, our SAP Manufacturing Execution team at Fortech delivered different types of customized modules for planning, monitoring and digitally controlling the production lines in factories and logistic facilities.

For a recent project, for a multinational client, our SAP Manufacturing Execution team at Fortech delivered different types of customized modules for planning, monitoring and digitally controlling the production lines in factories and logistic facilities.

The modules are used in factories from the entire industrial spectrum, but for one beverage company in particular our team delivered a tailored module used for the digital control of the making of flavored drinks. Through the intuitive UI, employees can send commands to the machines on the production line (start the mixing tank initiate the quality control analysis, add flavors & water, stop specific machines, transfer goods to other production lines, etc.).

Additionally, the RPA services offered helped the manufacturer automate specific processes:

Conclusion

Advanced factories of the future have already begun their digital transformation journey, and early adopters are gaining a competitive advantage. Companies that invest in emerging technology by implementing customized manufacturing software are creating the technical expertise and critical digital transformation culture required to succeed and thrive in the years ahead.

Customized manufacturing software development services are becoming a suitable solution for those businesses that are looking to support the smart manufacturing ecosystem by taking part in it. Moreover, Fortech can become your technology partner and help your business navigate through the revolution of the industry 4.0.

Fortech