For manufacturers, the complexity of today’s modern supply chains requires software solutions to make them sustainable, resilient, and agile

Marius Cadar, Client Executive

With his extensive background in software engineering and over 12 years of experience in the industry, Marius Cadar brings a unique perspective to the table when it comes to helping companies streamline their processes and increase efficiency through the use of software solutions.

Marius enables organizations to embrace digital technologies to improve agility, sustainability and scale the adoption of technology in a way that benefits all stakeholders. As an industrial manufacturing enthusiast, he is passionate about how Artificial Intelligence is transforming the industry and is always thinking of ways in which AI could help manufacturers overcome supply chain shocks and economic headwinds.

Home / Insights / InTechWeTrust / Marius Cadar

1. Manufacturers must develop a vision that can enable a different type of business model as supply chains face unprecedented challenges in the current context. How can software help manufacturers with the need for more resilient and agile supply chains?

Software plays a crucial role in helping manufacturers build more resilient and agile supply chains.

One of the benefits of becoming digital is gaining supply chain visibility. This allows manufacturers to be agile, make data-driven decisions, proactively mitigate disruptions, and react quickly to challenges.

Automation is another critical factor. Supply chain software can automate many processes involved in managing the supply chain, such as order processing, inventory management, and supplier management. This can help manufacturers reduce errors, save time, and improve efficiency.

Last but not least, collaboration. This is where supplier relationship management software comes into play. Manufacturers must foster open communication with suppliers and continuously monitor and evaluate supplier performance to ensure both parties achieve their goals. Supplier Relationship Management (SRM) software enables real-time communication with stakeholders and suppliers and contributes to solid relationships with suppliers.

Supply chains are transitioning from a stretched to its-limits linear global chain in pursuit of efficiency with close to zero resilience to a multi-segmented supply chain where sustainability, resilience, and agility play strategic roles.

Sourcing decisions will be based more on resilience rather than simply reducing costs. Manufacturers became used to an abundant supply of raw materials available from a single source, but the COVID-19 pandemic, the war in Ukraine, the ESG demands, and global tax reforms proved that the initial model needs a reset adapted to the new international situation.

2. Today, manufacturers are under tremendous pressure regarding sustainability. What steps can businesses in the industrial manufacturing sector take to drive meaningful environmental improvements across the board, and can a tech partner help?

Indeed, it is estimated that manufacturers account for 30% of global greenhouse gas emissions*, and leading manufacturers recognize the need for action in this area. Organizations need a holistic approach in defining a strategy towards net zero operations. Such a strategy could encompass activities like designing products with sustainability in mind, sourcing sustainable materials, improving operational efficiency, shipping, and distribution decarbonization, etc.

Technology is the key element across all these steps, and digital capabilities make the difference. For example, blockchain can be used to digitally track and trace individual materials, parts, and even finished products. For instance, this would be very useful for a company like Apple, which is looking to use recycled materials, like Aluminum, from its older models to build the newer versions of products and source other materials, like Cobalt, from certified recycled sources.

Digital twins can be leveraged to increase product and factory efficiency, schedule preventative maintenance and even improve the recycling process. Supply Chain Management software can optimize transport routes, type (by sea, plane, rail), and loads to reduce empty miles and CO2 emissions.

And these are just a few examples. A tech partner can help manufacturers become more sustainable by providing access to the right tools, expertise, and resources. By working with a tech partner, manufacturers can accelerate their sustainability journey and achieve meaningful results more quickly.

For manufacturers, the complexity of modern supply chains, as they evolve from the linear model to an actual network, makes meeting ESG regulations a challenge. Manufacturers should map their supply chain and overlay the environmental, social and governance (ESG) compliance goals. The ESG should serve as a guideline by which supply chain management strategies should be built.

A supply chain’s ESG performance level has become one of the crucial criteria when companies evaluate a potential provider.

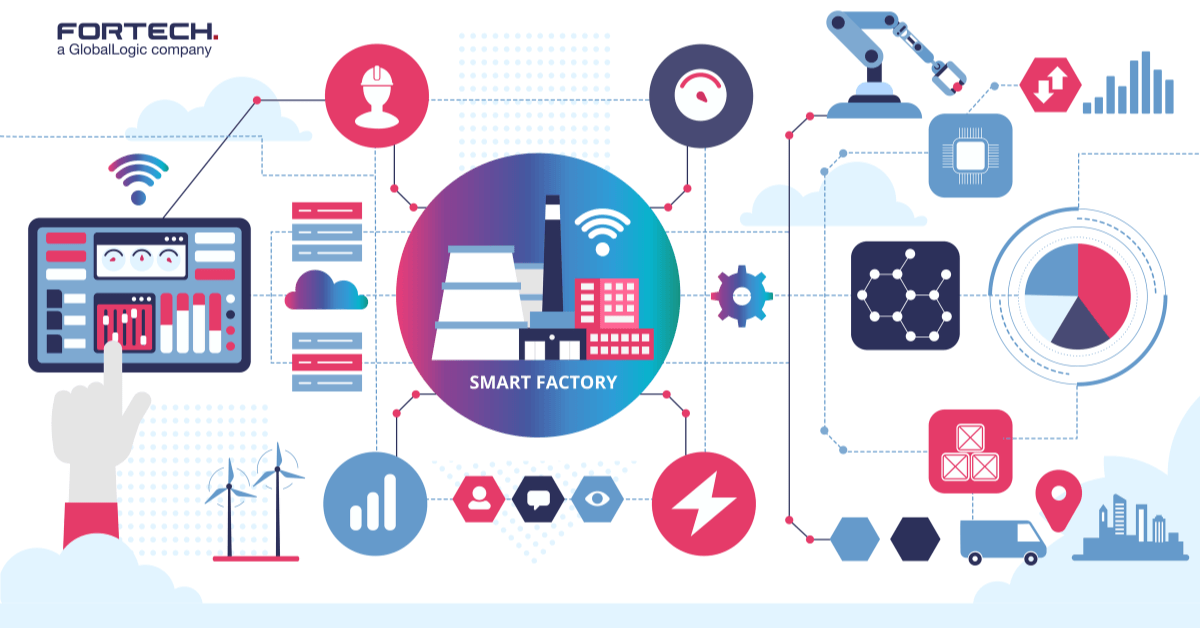

3. The concept of smart factories revolves around data gathering, in-depth analysis, and the ability to interpret and further use the information to optimize operations. In your opinion, how can manufacturers achieve this status, and what changes are necessary?

To reach the status of a smart factory, manufacturers need to integrate a range of digital technologies that enable them to gather, analyze, and interpret data from across their operations:

- IoT sensors, robotics and automation systems that can collect data in real-time and enable more effective monitoring and optimization of manufacturing operations;

- Data analytics tools and custom build software platforms to interpret the collected data and offer insights into operational performance, identifying areas for improvement and anticipating future trends;

- AI and Machine Learning to analyze large amounts of data and automate decision-making processes.

Fostering a culture of innovation is also necessary to fully leverage the benefits of smart factory technologies. For example, manufacturers might need to retrain their workforce to work alongside automated systems, establish new data governance policies, and adopt new business models that leverage the benefits of real-time data insights.

4. Give us an example of a smart factory that fits the profile: “The factory of the future.” Tell us why.

One example that comes to mind is Infineon’s Smart Factory in Dresden, Germany.

The semiconductor manufacturing plant has reached an automation level of 92% by using Industry 4.0 technologies. Alongside robots and other machines handling the assembly and testing of semiconductor devices, the factory also uses digital twin technology to create a virtual replica of the production process, allowing for real-time monitoring and optimization. Also, the smart factory is sustainable by using energy from renewable sources and having a closed-loop water system that recycles and reuses water.

5. Which do you consider is the most significant tech innovation that irrevocably changed the course of industrial manufacturing?

Over the years, we have seen several significant tech innovations that have had a profound impact on the course of industrial manufacturing. One of the most transformative technologies has been IoT, which has enabled greater connectivity, automation, and data-driven decision-making. This technology has helped manufacturers become more agile, responsive, and customer-focused, and it will undoubtedly continue to be an essential driver of innovation in the industry. What’s more, IoT is now fueling the advancement of AI and machine learning in the manufacturing sector, which can create a powerful synergy that has the potential to disrupt the industry and take it to the next level.

The estimated number of connected devices needed in a smart factory per square meter varies between 0,5 and 1**. Predictive maintenance is one of the essential IoT applications in Industry 4.0’s smart factories, but manufacturers can leverage IoT sensors for asset tracking, inventory management, quality control, energy efficiency, safety monitoring, and of course, supply chain optimization.

6. Let’s do a tech partner profile for a client in the industrial manufacturing Sector. What can a tech partner help with, and which are some of the characteristics that he requires?

A tech partner should have deep technical expertise in the relevant technological areas, such as automation, IoT, and data analytics. Beyond this, it also should have experience working with industrial manufacturing clients proven by a track record of delivering successful projects in the industry, including experience with project management, risk assessment, and quality assurance.

Last but not least, a tech partner should be innovative and creative, able to identify new opportunities for improvement and develop novel solutions to complex problems.

A tech partner with the right combination of technical expertise, industry experience, and collaboration skills can help industrial manufacturing clients achieve their goals, reduce costs, and navigate today’s and tomorrow’s challenges.

*Apple Environmental Progress Report, 2023

**Realizing smart manufacturing through IoT

Learn More About Our Industrial Manufacturing Software Development Capabilities

How We Enable Smart Manufacturing

We offer our clients manufacturing software development services to help them meet the needs of today’s manufacturing industry. From production and workforce planning to data analysis, predictive maintenance, cost optimizations, or logistics operations, we are the technology partner of manufacturers from various industries in a world where new technologies are surging ahead at a rapid pace.

Read MoreHow We Engineer Top-Tier Manufacturing Software

We are your partners in transformation. We help clients activate ideas and reach new solutions so they can take advantage of a new world of opportunities. We are a software development company that cares for your success especially since the events of 2020 have taught us about the importance of successfully navigating through disruptions.

Read More